Try our KIS.ME Starterkit for only EUR 499 – order now!

Process optimization and digitization made easy

KIS.ME

Keep it simple. Manage everything.

Simply digitize and optimize with KIS.ME, wherever people work – even at remote production sites or manual workstations. In no time at all, you can make your processes and your company more transparent and efficient.

Optimizing has never been so easy

KIS.ME can be used entirely without additional programming or IT knowledge. No software installation is required. Just plug it in, set it up, and go. Try it out now!

1.

Connect

The KIS.ME devices only require a power supply and a WLAN connection. This means that the devices can be used almost anywhere.

2.

set up

Configure KIS.MANAGER according to your needs. Create your digital store floor with your own set of rules or calculate the required key figures based on the collected data.

3.

Optimize

Once set up, data points and information are collected directly during running processes. From this data, everyone can identify optimization opportunities themselves and streamline their processes.

More effectiveness, less downtime

PRODUCTION KEY FIGURES

With KIS.ME, you can determine your key production figures in the simplest way possible. With the help of Overall Equipment Effectiveness (OEE), you bring transparency to your processes.

-

Availability

Easily capture the availability of your production facilities and manufacturing equipment.

-

First-Pass-Yield

Simply determine the output and first-pass yield.

-

Productivity

Simply visualize productivity and identify optimization needs.

Retrofit made easy

RETROFITTING AND PROCESS DIGITIZATION

With KIS.ME, you record the process data of your existing plants without intervening in the machine control system. This will take your production to a new level.

-

IoT Gateway

Easy data acquisition and control by means of digital inputs and outputs.

-

Digitization and automation

Simply digitize existing machinery and equipment and automate processes.

-

Plug & Play

Simply acquire and process existing sensor signals.

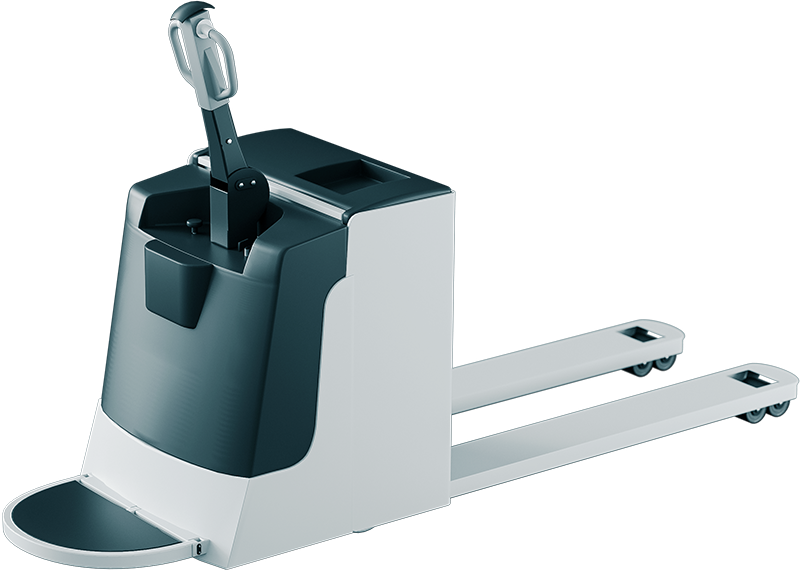

Shorter distances and faster material supply

OPTIMIZED INTRALOGISTICS

With KIS.ME you can optimize your intralogistics processes. Intelligent nibble control and efficient goods removal on demand shorten your supply chains and ensure a smooth process.

-

Smart Reordering

Simply automate the supply chain.

-

On time and on demand

Simply control the movement of goods efficiently.

-

Intelligent supply chain

Simply optimize the flow of materials.

Create transparency where it was previously impossible

CAPTURE MANUAL PROCESSES

With KIS.ME, you record process data from manual workstations or assembly activities. Capture data and control processes at the push of a button – it couldn’t be easier.

-

Call to action

Simply trigger actions or follow-up processes.

-

Alert

Simply report malfunctions or send a call for help.

-

Record process times

Simply record process times of manual work steps.

Record machine conditions and reduce downtimes

DIGITAL ANDON BOARD

With KIS.ME you get an overview of your plant utilization. Keep an eye on your production – fast, easy and uncomplicated.

-

Create transparency

Easily keep track of production status.

-

Reduce downtime

Simply increase productivity.

-

Signaling

Simple and clear signaling.

industry 4.0 also for small and medium-sized enterprises

TRANSPARENCY & EFFECTIVENESS THROUGH INTERCONNECTION

KIS.ME provides a remedy: increased transparency many times over without intervention in the actual control of the processes. This does not require a particular company size or specific industry. Whether manual workplaces, intralogistics or material supply; whether craft, industry or municipality – potential is everywhere. You can tackle downstream optimizations on your own and save time and money in the process.

With KIS.ME, you define and determine your own key figures, digitize existing machines or monitor your processes in real time – without any programming and without external consultants. Finally, get relevant data where you’ve always looked for it.

Digitization, optimization and increased efficiency with KIS.ME

Simply Solved

Efficient intralogistics

Wherever there is production, there must also be a flow of goods. Auxiliary materials and raw materials must be brought to the production site, and finished goods or waste materials must also be transported away.

With KIS.ME, this transport of goods can be controlled in a very simple way and also optimized and streamlined.

Transparent processes

Even in the age of automation and digitization, there are still many manual processes that are carried out by people.

This is precisely where KIS.ME steps in and simply digitizes these manual workstations to uncover the potential for optimization here as well.

Intelligent

retrofit

Many existing machines and legacy plants do not provide the desired information on their productivity and utilization.

With KIS.ME, existing plants and machines can be digitized in the simplest way possible. Without intervention in the control system, key figures can be determined and processes can be optimized. Retrofit made easy!

kis.me - the tool for SME digitization

success stories with kis.me

Significant increase in productivity

ifm electronic GmbH recognised the need for process optimisation in the area of central data acquisition and transmission in sensor production. Thanks to the simple integration and configuration of KIS.ME, errors in production can be detected and eliminated at an early stage and existing resources can be used in a more effective manner. This has achieved a significant increase in productivity.

over 60 hours of time saved per year per production line

ELESTA was looking for a simple solution to digitize assembly workstations. Previously, 15 min per day, each before the end of the shift, were used to record defects and document the production piece counts. With KIS.ME, non-value-added time could be completely eliminated.

Our customers and partners have already used KIS.ME successfully– and with great satisfaction.

Due to the quick and easy integration into the own processes, the added value for the users is visible very quickly.

THANKS to KIS.ME we have less downtime on our production lines. KIS.ME was installed really quickly.

Kevin Mehr

Head of production

KIS.ME gives us the transparency we need in production to ensure optimum process control for people, machines and materials.

Stefan Metzger

Director Production

KIS.ME helps us on our way to digital manufacturing. Transparency is the basis for economical and modern production

Eric Bulach

Director Strategy | Products | Markets

KIS.ME brings production to a smart level without great complexity

Joachim Walter

Chief Operating Officer

KIS.ME provides transparency and thus forms the basis for monitoring, analyzing and optimizing processes

Simon Wetzel

Head of Lean Management

KIS.ME captures data on-the-go and can save enormous effort, thereby increasing productivity.