Try our KIS.ME Starterkit for only EUR 499 – order now!

Success Story E-Towers FAMBA S.A. , Polen

Digitized Machine Maintenance with KIS.ME

Through the application of KIS.ME, an international company E-Towers FAMABA S.A. performed a significant step in the scope of Industry 4.0. In particular, it was able to digitalize the information flow related to the maintenance of their machines. This contributed to the significant gain of time both in the maintenance itself but also in all key figures and reports related to its realization

“The application of KIS.ME made it possible to solve the full information flow problem concerning machine maintenance. Starting from the machine failure report through the selection of the optimal maintenance team and up to the complete service accomplishment, KIS.ME makes the entire process transparent and maximally efficient.”

- Robert Zybaczyński M.Sc, B.Eng. , technology manager at E-TOWERS FAMABA S.A.

THE CUSTOMER PORTRAIT

E-Towers FAMABA S.A.

Company description

The roots of the company can be traced back to 1946 while its products cover wind towers and steel structures for cranes (with a weight up to 160 tons). In particular, the production process includes but it is not limited to:

> metal sheet pre-blasting

> transforming steel plates to steel constructions

> 4-roll plate bending

> welding steel

> large CNC machine-based processing

> cleaning and painting

> assembly and storage

The mission of E-Towers FAMABA S.A. can be summarized as a production of the highest quality steel construction through the commitment and competence of the crew as well as partnership cooperation with the client. Moreover, the strategic goal of the company is the optimal management of available resources in the pursuit of a stable increase in company value, while maintaining the highest standards of product quality and work safety

THE CHALLENGE

Digital transformation of the machine maintenance process

E-Towers FAMABA S.A. was looking for a way to improve the maintenance information flow, and hence, minimize the time between reporting a machine failure and the one of its final repair. In simple words, the new approach should maximize the machine production availability and minimize unappealing downtimes. The company was already using Grafana software for the monitoring and visualization of their machines. Thus, the crucial assumption was that the new maintenance system should be integrated with Grafana. Moreover, it should use its alarm notifications channels, which employ a dedicated Slack messenger mobile application. Finally, the system should provide the following physical functionalities:

> an easy way for reporting machine failures by the operator

> a straightforward failure-depending (electrics, mechanics, automatics) selection of the desired maintenance team

> visualization of the maintenance information flow

> automated calculation of key performance indicators (KPI) related to the maintenance process

> automated reporting related to the machine health and the associated KPIs

“The crucial point on the way to settle the above challenge was to use a platform with intuitive HMI hardware, which is inherently connected with a suitable software architecture. KIS.ME constitutes an optimal candidate to the above-stated problem. Indeed, KIS.ME Devices and KIS.MANAGER are fully compatible with all stated requirements.” - Marcin Witczak

Our contact person

Robert Zybaczyński

technology manager at E-Towers FAMABA S.A.

Our contact person

prof. Marcin Witczak

CONTROLINTECH

KIS.ME Partner

THE SOLUTION

The integration process was initiated by designing a suitable hardware architecture for each of the maintained machines, which should enable simple and intuitive:

>failure reporting

> acknowledging the failure by the master supervisor and calling the selected maintenance team depending on the failure (electrical, mechanical, automatics),

> acknowledging the maintenance call and performing a recovery action

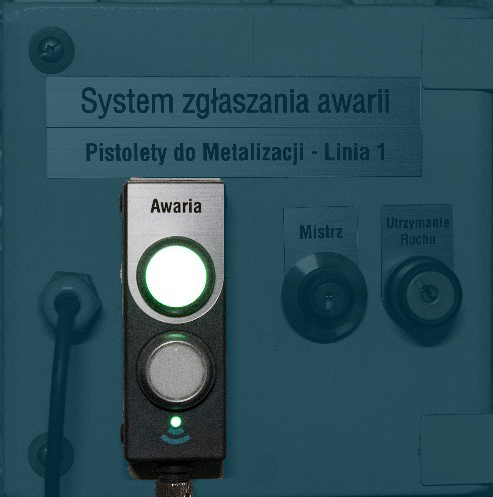

"With KIS.ME, failure reporting boils down the pressing KIS.BOX Button 2, which normally lights in green. As a result, its colour changes to the red one that indicates a failure. The acknowledgement of a failure was also realised in a simple and intuitive way. Indeed, each KIS.BOX has digital inputs and outputs, and hence the inputs are simply connected with different hardware keys for the master supervisor and the maintenance teams. Owing to the simplicity of the hardware architecture there is no need for special training of the staff involved in the entire maintenance process "

Description of the functions of KIS.ME in the machine maintenance process:

Having a hardware architecture, the application business logic was developed with KIS.MANAGER software that obeys the following rules:

1) After reporting a failure (KIS.BOX Button 2 colour red), the master supervisor selects the maintenance team by pressing KIS.BOX Button 1. As a result, its colour is cyclically transferring through different colours with the following meaning:

> black (not lighting) – master supervision and operator perform the maintenance by their own

> yellow – the automatics maintenance team is needed

> blue – the mechanics maintenance team is needed

> white – the electrics maintenance team is needed

After selecting an appropriate option, the master supervisor acknowledges his choice by using the master key.

2) Assuming that one of the maintenance teams is required, the arrival of the team is acknowledged with the maintenance key. From that moment the recovery action is performed until the key is removed.

3) The maintenance accomplishment is realised by pressing again KIS.BOX Button 2, which changes its colour to green (normal operation of the machine).

This action requires the presence of either master or maintenance team key.

All the above actions are realised with a dozen or so IF-THEN rules, which are visually developed within KIS.MANGER. From that moment, the transition times between all the above-listed states are recorded by KIS.MANAGER.

KIS.API a practical way for connecting external applications

One of the above-stated challenges was to connect the developed hardware and software infrastructure with Grafana. Grafana is already used by E-Towers FAMABA S.A. for the visualization and monitoring of their production machines. It also possesses a very intuitive alarm notification mechanism, which has to be adapted for the maintenance alarm notification. To settle the above challenge, KIS.ME provides REST API-based communication mechanism, which is called KIS.API. As a result, the integration of Grafana and KIS.ME was realised in a very straightforward way. Finally, special communication channels were defined in Grafana, which allow maintenance calls and messages among the teams using Slack messenger.

THREE ADVANTAGES IN THE SPOTLIGHT

Digitalization, optimization and transparency

DIGITAL TRANSFORMATION

Tracking of all important maintenance KPIs and thus identification and elimination of bottlenecks

OPTIMIZATION

- Optimized maintenance

- Improved performance of maintenance teams

TRANSPARENCY

- the machine availability

FUTURE OUTLOOK

Implementation of KIS.ME in production and logistics processes

After a short adaptation period of the new maintenance system, E-Towers FAMABA S.A. will extend its manufacturing and logistics processes with KIS.ME-based solutions. In particular, the following crucial initiatives are planned:

Quality control management:

The quality control system of the company is distributed, which means that there is no single point devoted for that purpose. Instead, the quality control team is requested to come to particular assembly points. Thus, an optimal and on time scheduling of their work is of paramount importance.

KIS.ME offers an optimal solution to solve this challenge.

Dynamic lighting system for optimizing intralogistics:

E-Towers FAMABA S.A. manufactures very large crane components and towers for wind turbines. This clearly rises the need for an optimal arrangement during their indoor transportation. Thus, the development of KIS.ME-based dynamic and flexible communication light system is also planned. It will cover a set of predefined production/transportation scenarios expressed in different communication permissions corresponding to different light settings. As a result, the entire production/transportation safety and effectiveness will be significantly increased.