Try our KIS.ME Starterkit for only EUR 499 – order now!

WOULD YOU LIKE YOUR Intralogistics even more efficient can be designed?

Intralogistics with KIS.ME

the simple solution for digitally transforming your logistics

"With KIS.ME, you can easily implement optimizations in production and intralogistics to save time and money.".“

- Simon Wetzel, Head of Lean Management RAFI

THE TASK

Wanted: Measurability of the efficiency of intralogistics

In production companies, it is very important that intralogistics works efficiently and supplies production with materials as required and collects finished goods from production. A good logistics service saves expensive production space and thus offers room for growth. It is not only important that production is optimally served, but also that intralogistics is used efficiently. This applies in particular to remote production units that still need to be accessed regularly. The situation is similar with waste stations, which should be taught on-demand. Transporters should only call at such stations if there is an actual need for them.

A clear and central display of the store floor with an up-to-date display of the jobs or the requirements from production for intralogistics is very helpful here. A simple transport requirement from production to intralogistics is a great advantage here. It is important to avoid unnecessary phone calls and time-consuming emails. Being able to measure the efficiency of intralogistics is the first important step towards operational intralogistics that is tailored to the needs of internal customers.

THE SOLUTION

Optimized intralogistics - SMART, DIGITAL AND SIMPLE WITH KIS.ME

One or more store floor boards can be set up easily via the KIS.MANAGER software platform and displayed on any device with a web browser. This ranges from the large overview monitor directly in the intralogistics headquarters to the logistics manager’s PC. Mobile access is also very easy thanks to the browser application.

The overview of the building structure with the departure stations makes the jobs to be done visible everywhere and at all times.

Various graphical elements such as bar charts or pie charts are also available for the graphical display of intralogistics key figures, which can be defined and parameterized independently as required. This makes it easy to visualize and measure the efficiency of intralogistics in order to allocate the necessary personnel as required.

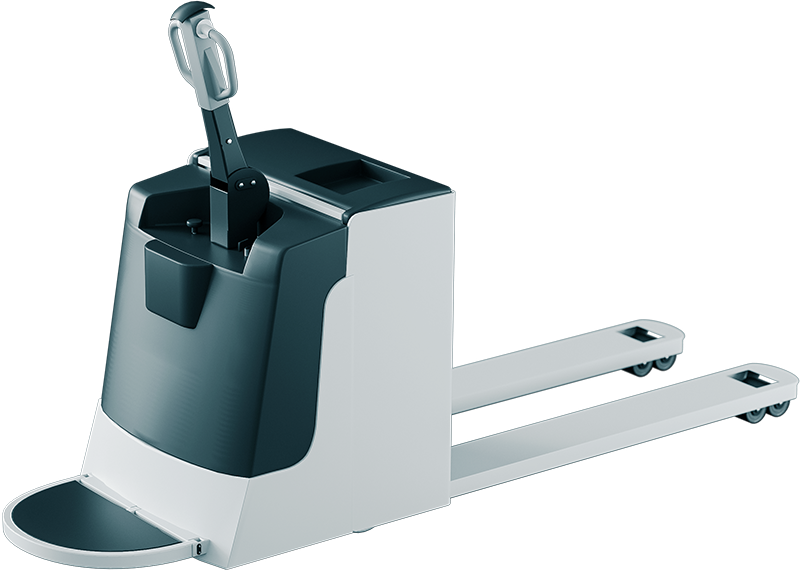

The logistics service is requested via the use of KIS.ME devices. Here, logistics can be requested via the KIS.BOX at the touch of a button. Thanks to the WLAN-capable devices, this also works across halls and factories. It is also possible to automate the logistics call via integrated digital inputs in combination with a light barrier or other sensors. Intralogistics is always requested as soon as a required quantity of finished products is ready for collection. The transporters are also sent to places that may not be visible or are not on the main routes. This saves enormous distances.

In addition, logistics requirements can be seen from afar with the WLAN-capable KIS.LIGHT luminaire. This means that the transporters can be requested and controlled even without a large store floor board. The lights themselves can be positioned flexibly in easily visible locations. A good range of different mounting systems helps here. The WLAN connection is made via the “guest network” (VLAN / DMZ), which is generally available without additional IT investment. with the advantage that the production network cannot be negatively affected.

KIS.ME helps to realize a dynamic milk run. This saves distances and reduces logistics cycle times to the optimum. This is also an opportunity to implement modern logistics concepts.

This saves time and many kilometers for the transporters. At the same time, internal customer satisfaction is increased.

Video: Optimising your logistics with KIS.ME

Application example: KIS.ME in intralogistics

THE EFFECT

Achieving greater customer satisfaction while reducing the need for storage space

With KIS.ME, you can increase the supply frequency of production with the same number of personnel by concentrating on main supply routes. This results in greater customer satisfaction and a reduction in storage space in production.

By concentrating on the main supply routes while maintaining the same supply frequency, the total distances covered by the carriers can be reduced and efficiency can be increased by up to 10%. By concentrating on the main supply routes while maintaining the same supply frequency, the total distances covered by the carriers can be reduced and efficiency can be increased by up to 10%. The reduction in the total distance traveled per carrier can be up to 5 km per day, which has a significant impact on the health of employees.