Process optimisation and digital transformation made easy

KIS.ME

Keep it simple. Manage everything.

With KIS.ME simple digital transformation and optimisation is possible wherever people work, even at remote or manual workstations. This idea was our starting point. Now, with KIS.ME we offer you an innovative solution to precisely this problem. You can make your company more transparent in no time by interconnecting manual processes, for example. Optimisation has never been easier – and it requires no additional programming or management consulting. Connect, set up, and go. Try it out now!

1.

Connect

In the simplest application, KIS.ME only needs a power connection and WLAN. This greatly simplifies the installation process.

2.

Set up

KIS.ME must be set up once. To do this, the KIS.ME devices need to be added to the KIS.MANAGER account and the WLAN network. After that, you are ready to go.

3.

Optimisation

Once setup is complete, data points and information are collected directly during ongoing processes. This data then enables everyone to identify optimisation opportunities and streamline the processes.

Easy-to-use automation

Optimise quickly and easily

There is potential everywhere, whether manual workstation, intralogistics, or material supply.

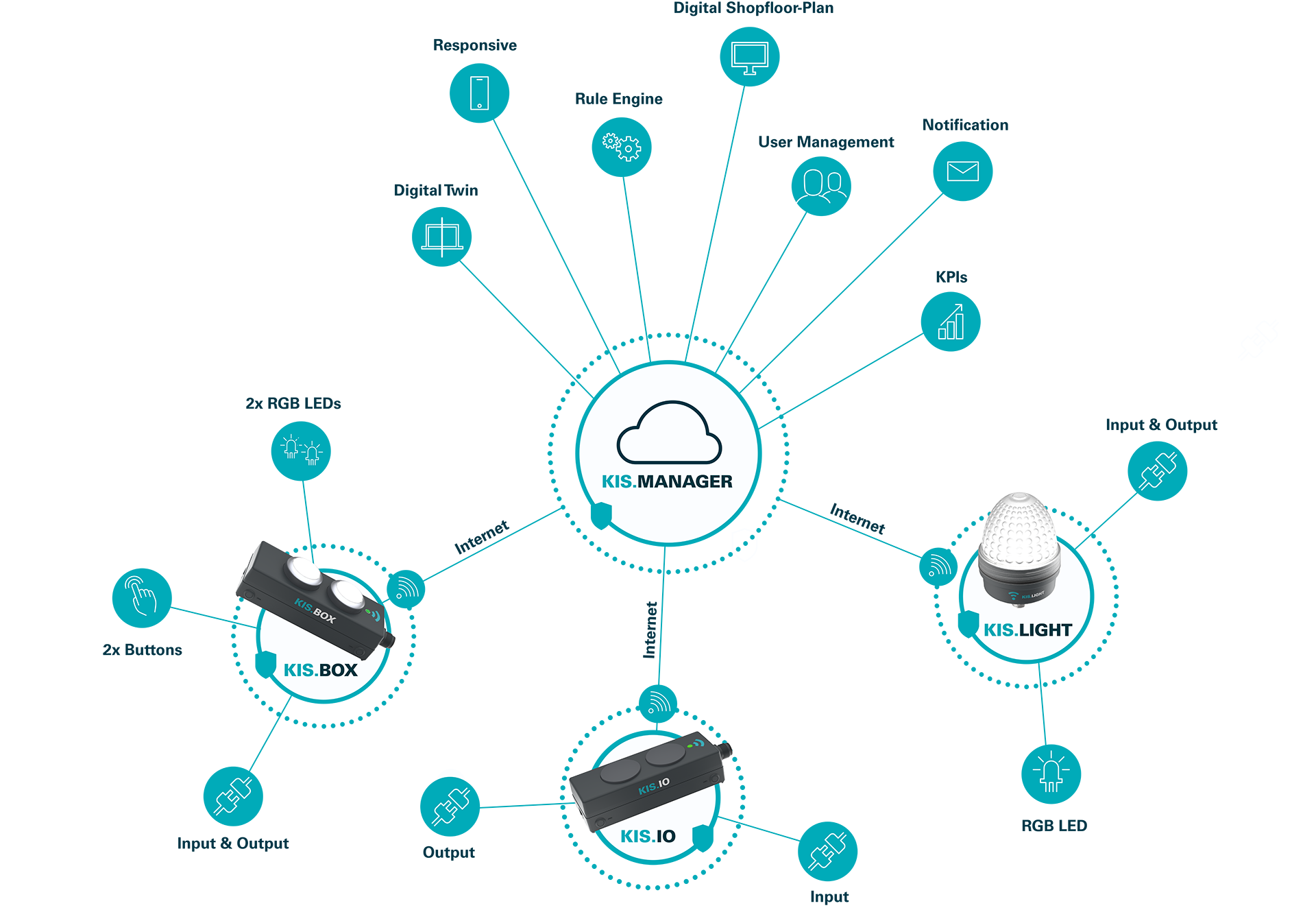

We have consolidated our expertise in electromechanics, electronics and software, because automation and digital transformation are frequently complex. We’ve done all of this to provide you with a product that you can easily use to optimise your production on a flexible basis: KIS.ME. This includes the signal lamp KIS.LIGHT, the control box KIS.BOX and the web portal KIS.MANAGER for configuration and evaluation. Modern machines and plants continuously collect data, some of which can be evaluated directly. However, nearly every machine and plant manufacturer has its own system, which can make it a challenge to keep an eye on everything. In contrast, it is often the case that no data at all is collected from manual processes, making it difficult to identify any optimisation potential.

KIS.me – the perfect hardware and software solution:

KIS.LIGHT

The KIS.LIGHT is a signal lamp that can light up and flash in RGB colours, visually indicating various statuses. In the most common application, the KIS.LIGHT can replace a conventional machine lamp while also transmitting the machine states to the KIS.MANAGER.

KIS.BOX

The KIS.BOX has two pushbuttons, each of which can be illuminated with various RGB colours. These buttons register human inputs and transfer them to the KIS.MANAGER. At the same time, certain events and statuses can be displayed to the user using the RGB buttons. Like the KIS.LIGHT, all KIS.ME devices have two digital inputs and two digital outputs. These can be used to detect external signals or trigger other machines and plants.

KIS.IO

Like the KIS.BOX, the KIS.IO has two digital inputs and two digital outputs. With the KIS.IO, however, the focus is on these inputs or outputs, with the buttons and RGB indicator fields being omitted. The KIS.IO is therefore mostly installed in existing machines and plants where no human process input is necessary.

KIS.MANAGER

The KIS.MANAGER is the centrepiece of KIS.ME. All devices can be managed and controlled with the KIS.MANAGER. Simple rules can be used to generate automated procedures and thus optimise processes. You can keep track of your own machines and plants at all times using digital shopfloor plans.

Industry 4.0 also for SMEs

Transparency & effectiveness through interconnection

Many talk about it, but we actually offer it: tangible digital transformation of manual workstations.

KIS.ME is the answer, providing greatly increased transparency without interfering with the actual process control. It’s not limited to a particular company size or specific industry. There is potential everywhere, whether manual workstation, intralogistics or material supply, whether trade, industry or local authority. You can optimise downstream processes yourself, saving a lot of time and money.

With KIS.ME you can define and determine your own KPIs, digitally transform existing machines, or monitor your processes in real time – without any programming or external consultants. Finally, you get relevant data where you’ve always wanted it. The desired outcome was the digital transformation of manual workstations with a focus on transparency, effectiveness and sustainability.

Specific applications in which kis.me can help you

KIS.ME applications

Many talk about it, but we actually offer it: tangible digital transformation of manual processes and easy retrofitting of existing machines.

KIS.ME can be used in just the way you need it, making it very versatile. In the first step, however, we designed KIS.ME for industrial use – for everywhere where production takes place and people work. We have defined three primary application areas:

- Intralogistics

- Manual workstations

- Retrofitting

The following three videos illustrate the possible applications of KIS.ME in these three areas:

Optimise intralogistics quickly and easily

Wherever there is production, there must also be a flow of goods. Auxiliary materials and raw materials need to be brought to the production site, and the finished goods and waste materials need to be transported away. With KIS.ME this transport of goods can be easily controlled as well as optimised and streamlined.

https://youtu.be/C0VRiWHgoiM

More applications

Make processes transparent

Many machines and plants today are already intelligently interconnected and provide the desired data for optimisation. However, there is also a lot of manual work that is still done by people. What does digital transformation look like in these cases?

KIS.ME intervenes in this context to digitally transform these manual processes and manual workstations with ease in order to reveal the potential for optimisation here as well.

https://youtu.be/H6cCUjNHcLg

More applications

Smart digital retrofitting for Industry 4.0

Many machines and plants have been successfully in productive use for several years. No one thinks of replacing them, as they usually work perfectly. But what if they stop working one day? Are these machines already so modern that they automatically sound the alarm and inform the responsible machine operator? Do these plants provide the desired information on productivity and other key performance indicators?

With KIS.ME, existing plants and machines can be digitally transformed in the simplest way possible. Retrofitting made easy!

https://youtu.be/AAonZ9x4_5s

More applications

KIS.ME – the tool for the digital transformation of small and medium-sized enterprises

Success stories with kis.me

The secret is out – KIS.ME has been a success in real-world use for several years now.

We don’t want to hide this fact – on the contrary. Here we show you practical examples from customers who are successfully making practical use of KIS.ME – and who are very satisfied with their decision to choose this product.

Elesta is saving more than 60 hours each year thanks to KIS.ME

ELESTA GmbH was looking for a solution to digitally transform its manual workstations. They previously had to spend 15 minutes per day recording and reporting faults at the end of each shift. Once they began using LEAN production methods, it was no longer appropriate for them to spend our time this way.The desired outcome was the digital transformation of manual workstations with a focus on transparency, effectiveness and sustainability.

< >

Read more about this success story

One click and you’re ready to go

Order the starter kit now and try out KIS.ME easily and at no obligation.

Order now