Try our KIS.ME Starterkit for only EUR 499 – order now!

PROCESS OPTIMISATION AND DIGITAL TRANSFORMATION FUNCTIONS AT A GLANCE

KIS.ME FUNCTIONS

THE PERFECT HARDWARE AND SOFTWARE SOLUTION

Digital transformation doesn’t have to be complicated. With KIS.ME, you can interconnect your manual processes in logistics and production in no time at all, increasing transparency and efficiency in the process. Try it out now!

In the following sections, we will show you the KIS.ME solution in detail.

HUMAN-MACHINE INTERFACE

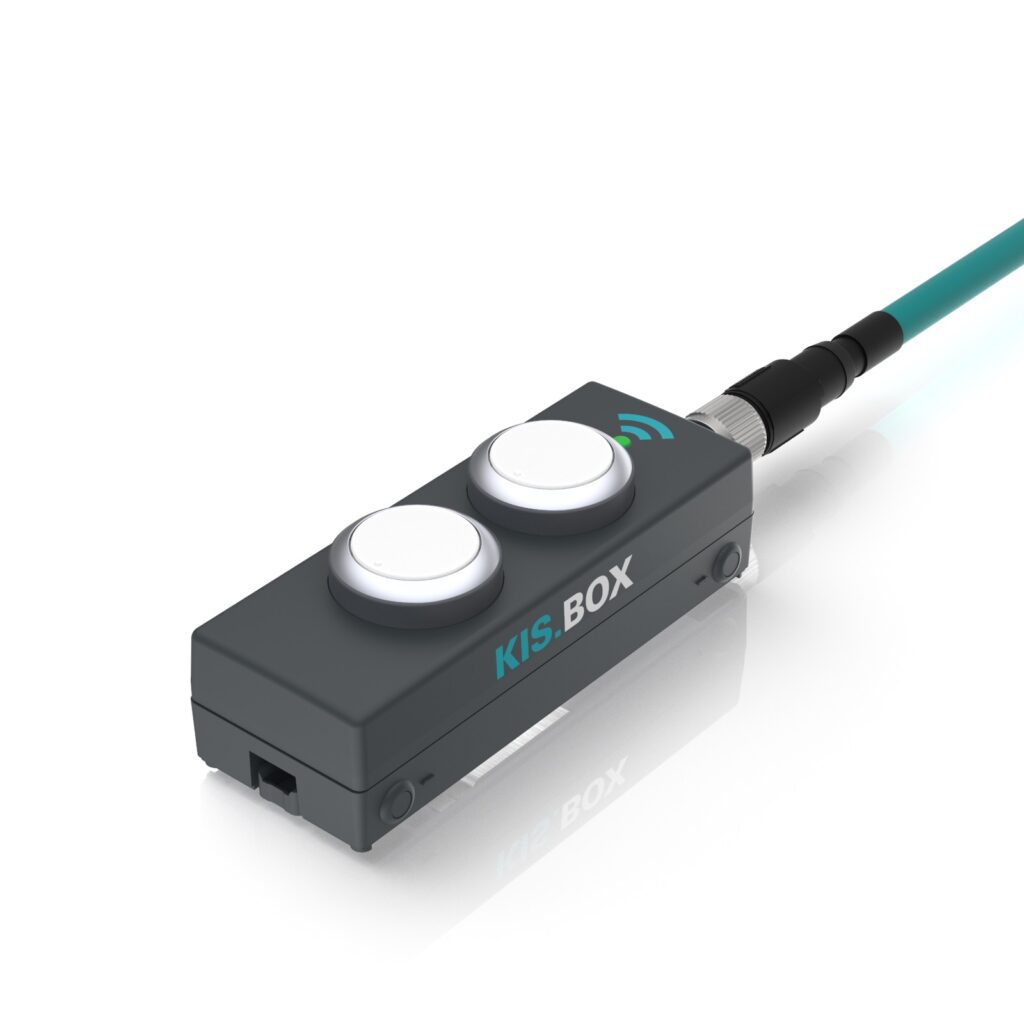

kis.box

A CONTROL BOX WITH INTEGRATED WLAN INTERFACE THAT CAN BE PLACED ON A DISTRIBUTED BASIS.

The freely configurable buttons integrated into the control box can be used to control any actions or activations. WLAN connectivity can be used to transmit each keystroke directly to the KIS.MANAGER in the cloud. All of this gives you maximum flexibility and control. A custom function can be assigned to each keypress. These functions might include alerting an employee, requesting material or reporting a malfunction. The customisable labelling of the buttons makes the KIS.BOX an intuitive message system.

Digital inputs and outputs are also available on each KIS.BOX, allowing external signals to be processed automatically. With the digital inputs, sensor signals or information from existing installations can be acquired very easily, regardless of what sensor you use or what plant you want to retrofit. All required data is transferred to the KIS.MANAGER, where it can be processed. The digital outputs can even be used to control external actuators, thus enabling smart control of your existing plants.

OPTICAL SIGNALLING

kis.light

A MULTI-COLOURED SIGNAL LAMP WITH INTEGRATED WLAN INTERFACE.

The KIS.MANAGER is used to control or activate the signal lamp. In this way, the signal lamp can respond to various digital events and indicate a variety of different states.

Thanks to the additional digital inputs, the signal lamp can also detect machine states or other digital signals at any time and transmit them to the KIS.MANAGER. This makes it very easy to replace or expand existing signal lamps and to digitally transform the statuses of existing machines and plants. The digital outputs can even be used to control external actuators, thus enabling smart control of your existing plants.

RETROFIT FOR MACHINES AND PLANTS

kis.io

A SMART WLAN BOX THAT PROVIDES TWO DIGITAL INPUTS AND TWO DIGITAL OUTPUTS.

The inputs allow different signals to be acquired, digitally transformed and used for smart control with the help of the KIS.MANAGER. Sensor signals from various sensors can be acquired, such as light barriers, proximity switches or thermostats, as well as status messages from existing plants or production equipment, such as end-of-line testers. All signals are transmitted to the KIS.MANAGER, where they can be processed.

The digital outputs of the KIS.IO can also be controlled via the KIS.MANAGER. Thus, you can regulate any information and activation from the cloud and thus intelligently manage and control your processes.. The KIS.IO thus becomes the digital gateway of your existing systems and is thus ideally suited for retrofitting and modernising your processes.

CONTROL CENTRE

KIS.MANAGER

A DYNAMIC CLOUD PLATFORM AS A COMMAND CENTRE FOR ALL KIS.ME DEVICES

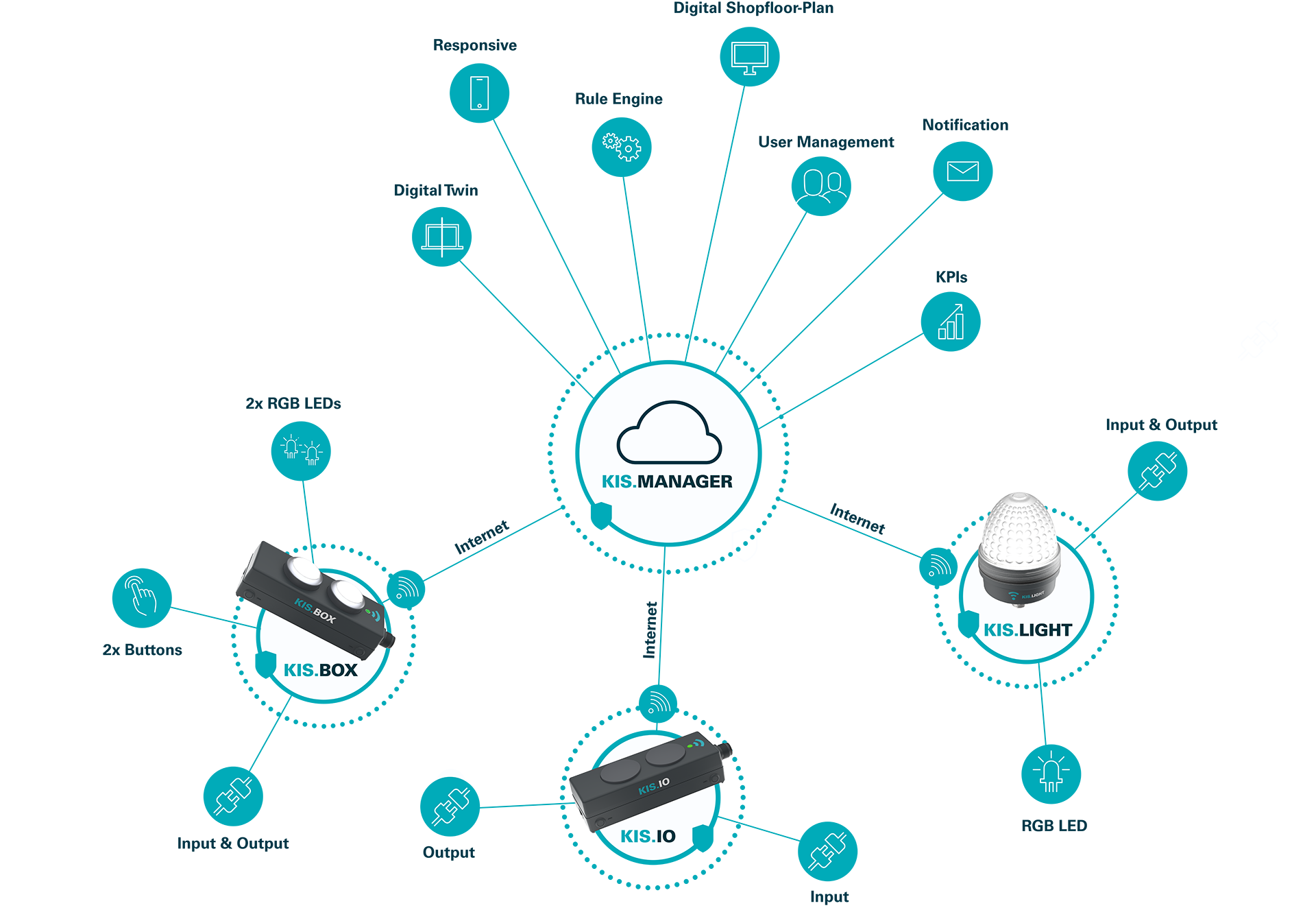

The KIS.MANAGER is the centrepiece of KIS.ME. The cloud platform is the command centre for all KIS.ME devices. All events can be managed and controlled with the KIS.MANAGER. All data from the KIS.ME devices is stored and can be visualised for evaluation and optimisation of your processes. The data can be used to calculate key performance indicators, and simple rules can be used to generate automated procedures and optimise processes.

The KIS.MANGER allows you to keep track of your own machines and plants at all times, increasing transparency along the way. And the best thing about it is that there is no need for a local installation for the KIS.MANAGER. This eliminates the need for costly IT resources and time-consuming maintenance work.

KIS.ME ENVIRONMENT

TRANSPARENCY & EFFECTIVENESS THROUGH INTERCONNECTION

THE KIS.MANAGER OFFERS A VARIETY OF DIFFERENT FEATURES TO HELP YOU OPTIMISE TRANSPARENCY, PROCESSES AND KEY PERFORMANCE INDICATORS.

KIS.ME provides a remedy: increased transparency many times over – without interfering with the actual control of the processes. This does not require a particular company size or specific industry. Whether manual workplaces, intralogistics or material supply; whether craft, industry or municipality – potential is everywhere. You can tackle downstream optimisations independently and save time and money in the process.

With KIS.ME you can define and determine your own KPIs, digitally transform existing machines, or monitor your processes in real time – without any programming or external consultants. Finally, you get relevant data where you’ve always wanted it. The desired outcome was the digital transformation of manual workstations with a focus on transparency, effectiveness and sustainability.

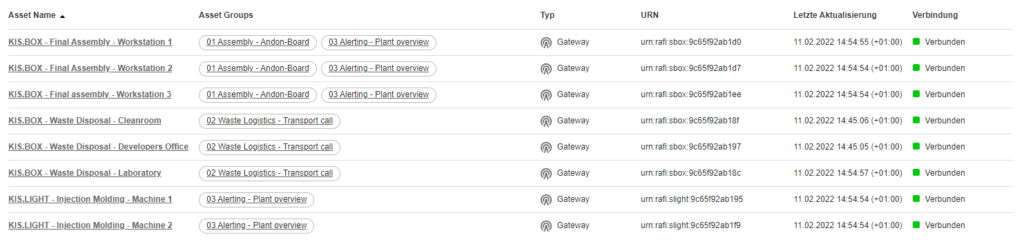

Device OVERVIEW

ALL YOUR KIS.ME DEVICES ARE MANAGED CENTRALLY USING KIS.MANAGER.

You can see at any time which of your devices are online, what their status is and what data has been acquired. If you would like, you can also receive additional information such as the serial number or MAC address as well as whether a firmware update is available.

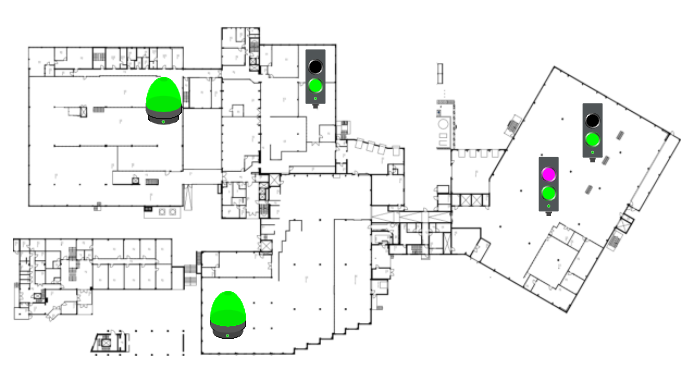

SHOP FLOOR PLAN

MAXIMUM TRANSPARENCY ABOUT THE STATUSES OF YOUR PROCESSES.

Using the digital shopfloor plan, you can create an overview of your production, logistics and maintenance processes.

Upload your own building map and place your KIS.ME devices in the right position using drag & drop. This gives you maximum transparency about the statuses of your processes.

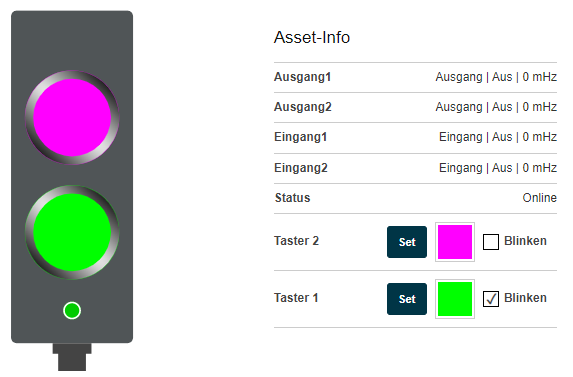

DIGITAL TWIN

ALL KIS.ME DEVICES HAVE A DIGITAL TWIN.

This twin reflects the real statuses of the devices, providing you with live statuses from your processes at a glance. The devices can also be controlled using the digital twin. For example, keypresses and colour changes can be activated at the click of a mouse.

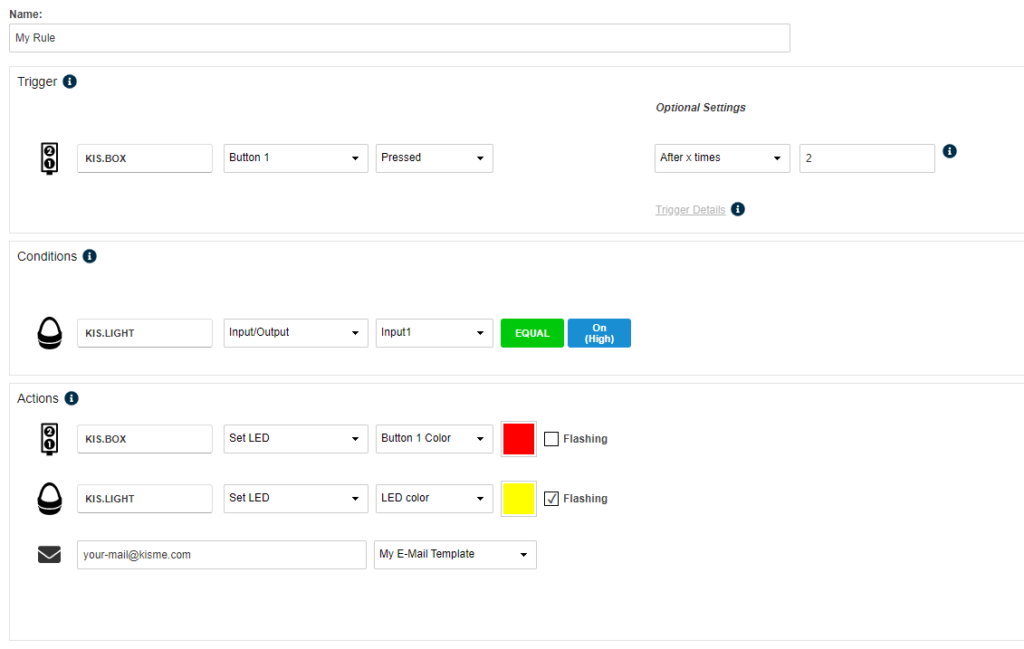

RULE ENGINE

THE RULE ENGINE TRANSFORMS THE KIS.MANAGER INTO YOUR DIGITAL CONTROL CENTRE.

Rules are activated by selecting one or more trigger events. You can also add different conditions that can be logically linked to each other.

In this way you obtain absolute control over when which rule is to be executed. When a rule is activated, the previously defined actions are carried out. Several actions can be controlled simultaneously also in this case, ranging from controlling a colour state to activating an actuator to sending an e-mail message. You have complete control over the management of your processes.

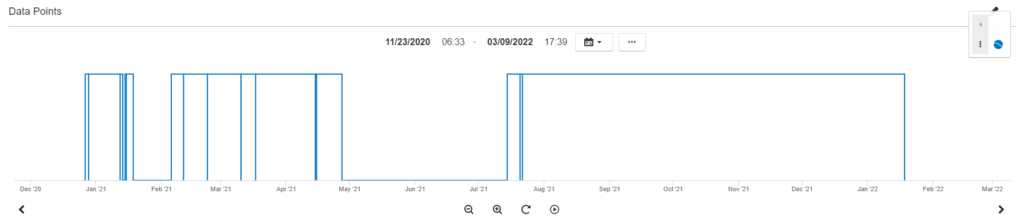

DATA ANALYSIS

ALL DATA THAT HAS BEEN ACQUIRED AND TRANSFERRED TO THE KIS.MANAGER IS STORED.

In this way you have complete insight into when a given event took place and can view both live and historical data. You can navigate through your data at any time and make the relevant events visible. This is the first step towards optimising your processes. You can see at any time when a key switch was pressed, when a plant had a malfunction or when the material replenishment took too much time. In this way, unusual events and conspicuous features are immediately visible, and it is also convenient to export and further process all data.

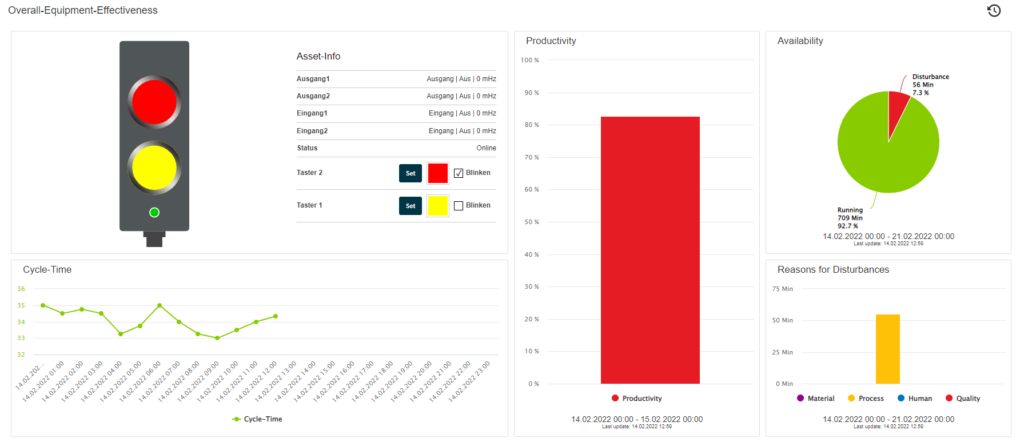

KPI CALCULATOR

MAKE KEY PERFORMANCE INDICATORS RELATING TO PRODUCTIVITY, EFFICIENCY AND AVAILABILITY VISIBLE.

Individual key performance indicators can be calculated and visualised using the KIS.MANAGER and the data collected by the KIS.ME devices.

Whether first-pass yield, downtimes or OEE key performance indicators, whether average values, maximums or totals. With the KIS.MANAGER, you can always keep an eye on everything. This creates transparency and supports you in taking your processes to the next level.

DASHBOARD

DESIGN YOUR INDIVIDUAL DASHBOARDS ACCORDING TO YOUR NEEDS AND REQUIREMENTS.

Whether digital twin, data history, shopfloor plan or key performance indicator diagrams, you can see all the crucial information at a glance. Use it to create Andon boards or to visualise your overall equipment effectiveness (OEE). Using the KIS.MANAGER, you can gain insight into all your internet-capable end devices from anywhere you want without installation.

WORKSPACES

THE KIS.ME DEVICES CAN BE COMBINED INTO VARIOUS GROUPS OR WORKSPACES.

The devices can be easily assigned to different applications in this way, creating clarity and facilitating your work, especially when several applications are equipped with KIS.ME.

NOTIFICATION

NOTIFICATION AT THE TOUCH OF A BUTTON – IT’S EASY WITH KIS.ME.

Create predefined e-mail templates and decide when you want to be informed. You can use the Rule Engine to create individual rules to activate a notification, whether you need a call system for when support is requested or you need to have alerts sent in case of downtime.

You have full flexibility as to who should be informed, when and with what message. This can also be combined with third-party systems to send a chat notification or an alert to the smart watch.

USER MANAGEMENT

KIS.MANAGER CAN BE USED BY DIFFERENT USERS WITH VARIOUS ROLES AND RIGHTS.

There is no limit to the number of users. You can independently add new users and assign rights to use KIS.MANAGER at any time.

A distinction is made between the following roles:

Admin: A highly privileged user who can manage the system (e.g. create users and assign devices to workspaces). This is usually the responsible KIS.ME employee. This role is automatically assigned when the company account is registered or created.

Installer:A user who is responsible for a specific group of devices or for a specific application (e.g. creating dashboards and shopfloor plans, creating rules and metrics). This is usually a foreman or a process manager.

Observer: A restricted user with read-only access. This is usually a production manager or managing director who does not want to configure the KIS.MANAGER himself.

Operator: A user with limited rights who can only control the digital twin within a specific workspace.

OVER-THE-AIR UPDATE

ALL KIS.ME DEVICES HAVE ENCRYPTED AND CERTIFICATE-BASED COMMUNICATION.

The certificates are renewed regularly and automatically. Likewise, new firmware updates for the KIS.ME devices are also made available on a regular basis. This means the devices can be updated where they are without you having to intervene.

You also have the option of storing individual update times. In this way you can decide when an update is carried out in order to prevent disruptions or interruptions of productive time. KIS.MANAGER is also regularly updated so that all software components are kept up to date. This happens in the background without affecting you.