Try our KIS.ME Starterkit for only EUR 499 – order now!

WASTE Logistics with KIS.ME

YOUR WASTE COSTS TOO MUCH TIME?

– Your waste disposal needs are difficult to schedule?

– Your waste stations are not centrally managed?

– The transport routes of your waste logistics are inefficient?

– Your intralogistics does not yet communicate digitally?

THE TASK

DESIGNING LOGISTICS PROCESSES EFFICIENTLY

The tasks in the field of waste logistics are manifold. Making the implementation of logistics processes efficient is a major challenge. In most cases, there is a lack of a central overview of all waste stations as well as digital communication so that logistical processes can run according to demand. Unnecessary journeys by transporters cost a lot of time and are therefore not economically viable.

THE SOLUTION

DEMAND-DRIVEN LOGISTICS

KIS.ME from RAFI offers a simple solution to these challenges. Thanks to their M12 interface, the KIS.BOX and KIS.LIGHT hardware components can receive digital inputs, for example from level sensors, and pass this information on to the KIS.MANAGER software platform via WLAN. KIS.MANAGER then provides a central overview of all waste stations equipped with KIS.ME.

The KIS.BOX can also be equipped with push-buttons, individually labelled and manually operated if required, if no level sensor is available or cannot be integrated.

This solution is used at RAFI, for example.

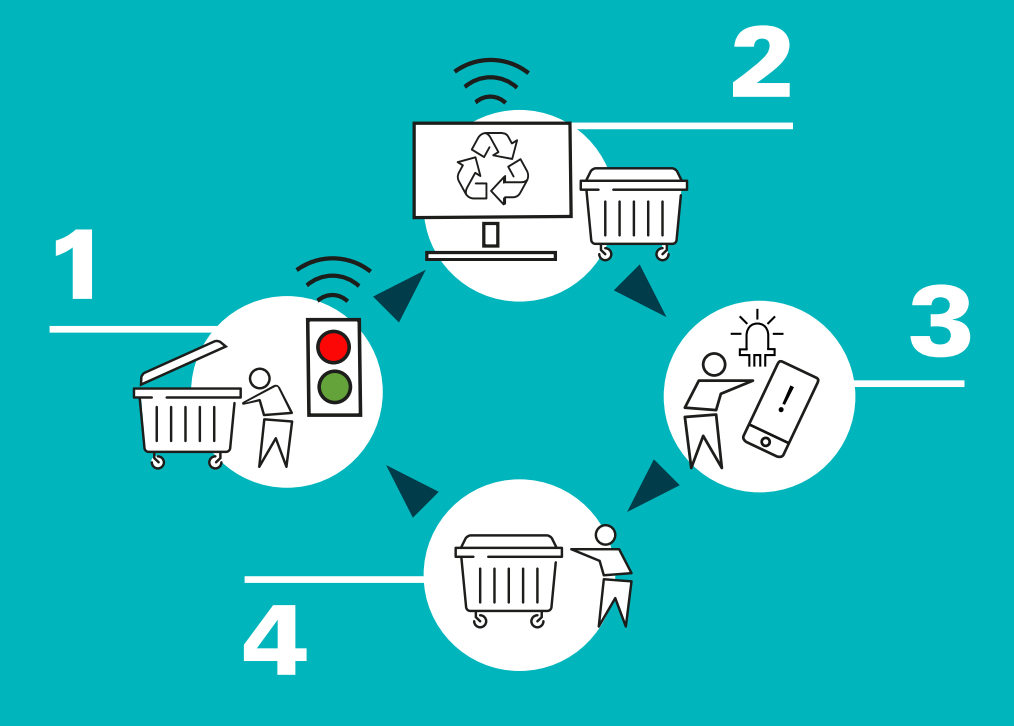

Step 1

When the trash can is full, waste disposal is requested at the touch of a button. The KIS.BOX transmits this information to the KIS.MANAGER via WLAN.

Step 2

In KIS.MANAGER, the store floor plan shows where disposal is required.

Step 3

Information reaches the conveyor via e-mail or optical display by means of KIS.LIGHT.

Step 4

The full container is replaced by an empty one in ONE way.

the effect

Cost savings through digital information transfer

The effect of KIS.ME is clearly illustrated by this example. The uncomplicated, digital transfer of information via WLAN enables targeted and efficient transport routes. Digital monitoring via KIS.MANAGER provides an optimal overview of all running processes around the clock. Overall, this results in significant time and cost savings.

Uncomplicated, digital communication

Targeted transport routes

Monitoring even of remote stations around the clock

Significant time and cost savings

Comparison

Time required without KIS.ME

195.5 hours per year: €9,775

Time required without KIS.ME

Time required with KIS.ME

92 hours per year: 4.600 €

Time required with KIS.ME

Thanks to the central overview in KIS.MANAGER, there is no need for daily checks. More effective and demand-driven logistics also halve the cost per emptying.

This means that KIS.ME can save €5,175 in personnel costs!

We still have to compare this saving with the costs for the KIS.ME solution:

Cost accounting

One time investment

Current costs

The one-time investment for the acquisition of KIS.ME as well as the ongoing operating costs are very low compared to the savings in time spent. The cost savings are somewhat reduced in the first year by the one-off investment costs, but from the following year the effective savings in this case are €2,847.

The return on investment (ROI) starts after only about seven months.

Practice Report

Intralogistics at RAFI

Christian Eyrich is Director of Logistics at RAFI. With KIS.ME, its carriers can now perform their logistical tasks

targeted and demand-oriented, and thus much more efficiently.

GO FOR IT!

Just start now

KIS.ME works very simply! Even without programming knowledge, you can set up and install KIS.ME with little effort and at low cost. The best way to start is with our KIS.ME Starter Kit, consisting of KIS.BOX, KIS.LIGHT and KIS.MANAGER.